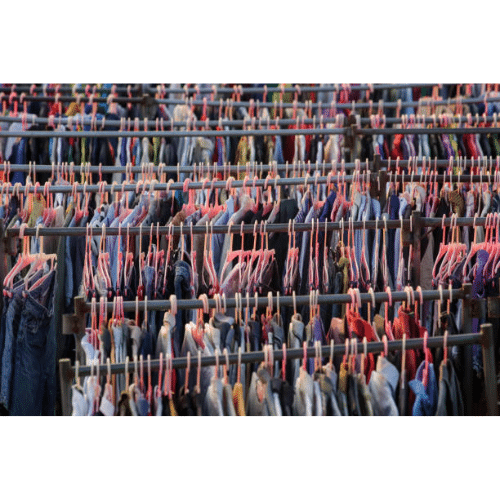

When it comes to crafting or fashion design, the right fabric can make all the difference. Wholesale fabrics offer a treasure trove of options for designers, tailors, and DIY enthusiasts alike. By purchasing in bulk, you not only save money but also gain access to a wider variety of materials, colors, and patterns that can elevate your projects.

Whether you’re creating stunning garments or unique home decor, understanding the wholesale fabric market is essential. You’ll discover how to choose the right supplier, what to look for in quality materials, and the benefits of buying wholesale. Dive into the world of wholesale fabrics and unlock the potential to bring your creative visions to life while enjoying significant savings.

Understanding Wholesale Fabrics

Wholesale fabrics refer to materials purchased in bulk at discounted prices from suppliers. This approach benefits fashion designers, crafters, and businesses looking to procure fabric efficiently.

What Are Wholesale Fabrics?

Wholesale fabrics are textiles sold at lower rates to those who buy in large quantities. These fabrics include various types such as cotton, polyester, silk, and linen among many others. The wholesale market often features numerous colors, patterns, and textures. Suppliers cater to businesses and individuals, providing access to both popular and unique fabric types. Generally, wholesalers enable purchases at prices significantly lower than retail.

Understanding wholesale fabrics involves recognizing that they are mainly sold to fulfill large orders. For instance, fabric stores, designers, and clothing manufacturers commonly purchase these materials. Furthermore, some wholesalers specialize in specific types of fabrics, ensuring you can find exactly what you need for your projects. By connecting with wholesale suppliers, you can access high-quality fabrics while benefiting from cost savings.

Benefits of Buying Wholesale Fabrics

Buying wholesale fabrics offers several advantages. First, cost savings stand out as the primary benefit. Purchasing in large quantities substantially reduces the unit price per yard, resulting in lower overall expenditure for your projects.

Second, variety plays an important role. Wholesalers often stock a wide range of fabrics, allowing you to explore numerous options. You can find different colors, patterns, and materials suitable for various applications. This diversity simplifies the selection process when working on unique design projects.

Third, consistency in quality occurs with reputable wholesalers. Buying from established suppliers means receiving uniform fabric quality across your orders. This consistency ensures that your finished products maintain the expected standards.

Fourth, availability significantly impacts your workflow. Wholesalers maintain substantial inventories, so fabric availability seldom becomes an issue. You can avoid delays in your projects by sourcing large amounts of fabric efficiently.

Lastly, minimum order requirements often lead to better pricing structures. While some suppliers impose minimum quantities, these quantities generally remain manageable for most businesses and creators. The investment in wholesale fabrics pays off through increased savings over time.

How to Source Wholesale Fabrics

Sourcing wholesale fabrics requires careful planning and research. Being informed about suppliers and industry standards boosts your buying experience.

Researching Suppliers

Start your search by identifying reputable wholesale fabric suppliers. Look for suppliers with established businesses and positive reviews. Utilize online platforms such as Alibaba, Wholesale Central, and Maker’s Row to find vendors. Check their websites for product catalogs and industry certifications. Evaluate their qualifications and customer feedback to assess reliability.

Attend local trade shows and fabric expos to connect with suppliers directly. Engage in conversations with industry peers for recommendations. Form relationships with your suppliers, as these connections can lead to better pricing and exclusive deals.

Compile a list of potential suppliers, noting their contact information, minimum order quantities, and fabric types available. This organized approach streamlines future communications.

Evaluating Quality

Assessing fabric quality is vital in sourcing wholesale textiles. Begin by ordering samples from your shortlisted suppliers. Examine samples closely for texture, weight, and durability. Ensure the sample matches your project requirements.

Understand fabric classifications such as woven, knit, or non-woven materials. Review their production processes, such as dyeing and finishing, which may affect the quality. Inquire about the sustainability practices of suppliers, as eco-friendly fabrics can be a selling point.

Look for certification labels that indicate quality standards, such as Oeko-Tex or GOTS for organic textiles. Check for consistent color and print across samples to ensure uniformity in larger orders. Ensure suppliers offer returns or exchanges if the delivered fabric fails to meet quality expectations.

Comparing Prices

Comparing prices among suppliers enhances your ability to secure the best deal. Gather quotes from multiple vendors, focusing on similar fabric types and quantities. Factor in shipping costs as they vary among suppliers and can impact the total price.

Analyze the pricing structures. Some suppliers may offer tiered pricing based on order volume, allowing for discounts on larger purchases. Assess the overall value, not just the lowest price. Reliable suppliers may charge more but provide better quality and service.

Negotiate pricing when possible, especially on larger orders. Cultivate relationships with suppliers. Some may provide loyalty discounts for repeat customers. Always be mindful of seasonal sales or promotional events that could affect pricing.

Purchasing Wholesale Fabrics

Purchasing wholesale fabrics involves understanding the specific terms and conditions set by suppliers. Knowing important aspects such as minimum order requirements, negotiation tactics, and the ordering process can make the purchasing experience efficient and beneficial.

Minimum Order Requirements

Minimum order requirements refer to the smallest quantity of fabric you must purchase to complete a transaction with a supplier. These requirements vary widely depending on the supplier and the type of fabric.

- Identify supplier policies: Review the policies of different suppliers to find those with favorable minimums. Some may offer as little as 5 to 10 yards, while others could require 50 or more yards.

- Evaluate project goals: Determine how much fabric you need for your projects or resale activities. If your intended usage is small, search for suppliers with lower minimum order quantities.

- Group purchases: Consider teaming up with other creators or businesses to meet higher minimums. Pooling resources can help you take advantage of bulk pricing while securing a wider variety of fabrics.

- Order samples: Request samples of fabric, even if you plan to fulfill the minimum order in bulk later. This approach allows you to assess fabric quality and suitability for your projects without committing to a large order.

Understanding minimum order requirements aids you in choosing the right supplier and maximizing your investment in wholesale fabrics.

Negotiating Prices

Negotiating prices effectively ensures you pay the best possible rates for your fabrics. A few strategies can help you secure better pricing.

- Research market prices: Collect information about average pricing for the fabrics you want. Knowing typical costs empowers you during negotiations.

- Inquire about discounts: Ask suppliers about discounts for larger orders or special promotions. Many suppliers offer incentives for bulk purchases of specific fabrics.

- Be clear about intentions: Clearly state your intent for future orders and your desire to build a long-term relationship. Suppliers may offer discounts when they see potential for ongoing business.

- Stay flexible: Be open to alternative fabrics or options that the supplier suggests. Alternatives could result in lower prices and still meet your project’s requirements.

- Follow-up offers: If you receive a quote from one supplier, share it with others to encourage competitive pricing. Suppliers often adjust their prices to match or beat competitors.

Employing these strategies enhances your chances of obtaining better pricing when purchasing wholesale fabrics.

Placing an Order

Placing an order for wholesale fabrics requires careful attention to detail to avoid mistakes. Follow these steps to ensure a smooth ordering process.

- Confirm fabric specifications: Double-check your fabric choices, including color, width, weight, and any specific patterns or textures you desire.

- Review supplier terms: Familiarize yourself with the supplier’s terms for payment, shipping, and returns. Clarity on these points can prevent misunderstandings later.

- Use ordering systems: If the supplier has an online ordering platform, utilize it for ease. Online systems often allow you to track your order and view shipping details.

- Maintain communication: Keep an open line of communication with the supplier throughout the ordering process. Quick responses to inquiries can help address any potential issues or concerns.

- Request confirmation: After placing your order, request a confirmation email. This documentation serves as proof of what you ordered and the agreed terms.

Following these steps ensures you place effective orders while minimizing risks in your wholesale fabric purchases.

Storing Wholesale Fabrics

Proper storage of wholesale fabrics ensures longevity and quality. Implementing effective storage techniques enhances your fabric management and keeps materials in great condition.

Best Practices for Fabric Storage

- Use fabric bolts or rolls. Rolling fabrics on bolts or cylindrical tubes prevents creases and damage. This method also saves space and makes identifying materials easier.

- Store fabrics in a cool, dry place. Humidity can lead to mold and mildew. Keep fabrics away from direct sunlight to maintain color integrity.

- Organize by type. Group fabrics according to categories like cotton, polyester, or silk. This arrangement simplifies locating materials for future projects.

- Utilize clear bins or containers. Transparent containers provide visibility of fabric contents. Label bins with fabric types and colors for quicker access.

- Fold larger pieces properly. When folding, avoid sharp creases. Maintain fold sizes to create uniform stacks, encouraging a neat workspace.

- Regularly check for pests. Inspect fabrics for signs of pests like moths or insects. If detected, use appropriate containment methods to protect other materials.

Preventing Damage and Deterioration

- Avoid heavy stacking. Excess weight can crush delicate fabrics. Store lighter materials on top when stacking to prevent damage.

- Use acid-free tissue paper. When folding fabrics, place sheets of acid-free tissue between layers. This protection prevents fabric prints and textures from transferring.

- Keep away from chemicals. Store fabrics away from cleaning supplies and chemicals that may cause discoloration or deterioration. Ensure the storage area is free of excess odors.

- Maintain proper temperature. Temperature fluctuations can weaken fabric fibers. Aim for a consistent climate to safeguard against deterioration.

- Limit exposure to air. Air circulates grime and dust that may affect fabrics. Consider using breathable covers for long-term storage, allowing air while protecting from dust.

- Use protective storage methods for specialty fabrics. For unique materials like silk, use protective bags or specialized storage solutions to address their specific needs.

Proper storage practices for wholesale fabrics significantly contribute to maintaining their quality and usability. Keeping an organized and well-protected fabric inventory supports efficient project workflows.

Cutting and Preparing Wholesale Fabrics

Cutting and preparing wholesale fabrics requires the right tools and techniques to ensure precision and efficiency in your project. This section outlines essential equipment and methods for achieving accurate cuts and preparing your fabrics for use.

Tools for Cutting Fabrics

Utilizing the appropriate tools ensures clean cuts and maintains the integrity of your fabrics. Essential tools include:

- Rotary Cutter: A rotary cutter features a circular blade, ideal for cutting through multiple layers of fabric. Use a cutting mat underneath to protect surfaces.

- Fabric Scissors: Invest in high-quality fabric scissors that cut smoothly. Keep these scissors solely for fabric to maintain their sharpness.

- Straight Edge Ruler: A clear straight edge ruler helps achieve straight cuts. Use it in conjunction with rotary cutters for better accuracy.

- Measuring Tape: A flexible measuring tape ensures accurate measurements when cutting fabric pieces.

- Chalk or Fabric Marker: Use chalk or fabric markers to mark cutting lines. Ensure that the marks are visible but easily removable.

These tools streamline the cutting process and help avoid errors, enhancing the overall quality of your fabric projects.

Techniques for Accurate Cutting

Employing proper cutting techniques leads to accurate and clean fabric pieces. Key techniques include:

- Measure Twice: Before cutting, double-check all measurements. Avoid mistakes by ensuring that the dimensions match your project specifications.

- Align Fabric Properly: Lay fabrics flat and ensure edges are aligned. This will prevent miscuts and frayed edges.

- Use Weights: Place fabric weights along the edges to hold the fabric in place while cutting. This prevents shifting during the cutting process.

- Cut in a Straight Line: For straight cuts, move the rotary cutter or scissors in a slow and steady motion. Avoid rushing to minimize errors.

- Cut with the Grain: Always cut along the grain of the fabric. This maintains the fabric’s integrity and prevents stretching or distortion.

By implementing these techniques, you prepare your wholesale fabrics effectively, setting the stage for a successful crafting or sewing experience.

Common Issues with Wholesale Fabrics

Wholesale fabrics can present challenges that buyers must address to ensure satisfactory purchase experiences. Understanding these common issues may help you navigate the wholesale fabric market more effectively.

Dealing with Defective Fabrics

Defective fabrics create significant setbacks for buyers. Identify defects quickly by inspecting samples before placing larger orders. Order smaller quantities first to assess fabric quality. When defects arise in large orders, communicate directly with suppliers regarding the issues. Suppliers often request photographic evidence of defects to support claims.

Document all communications with suppliers. Provide clear descriptions of the defects observed in the fabrics. Every detail about the fabric’s quality, such as texture inconsistencies, improper dyeing, or structural flaws, aids in addressing the problem. Request replacements or refunds based on the supplier’s return policy.

If suppliers grant returns, follow their guidelines for returning defective fabrics. Ensure to package fabrics securely to prevent additional damage during transit. Maintain records of all correspondence and returned items for future reference. Understanding the supplier’s policy before making large purchases reduces potential waste and disappointment.

Understanding Fabric Returns and Exchanges

Navigating fabric returns and exchanges requires awareness of supplier policies. Suppliers often provide clear guidelines on how to return items. Before making a purchase, review these policies. Familiarize yourself with return deadlines, restocking fees, and acceptable conditions for returns. Knowing these details beforehand ensures smooth transactions.

In general, contact suppliers promptly when a return is necessary. Detail your reasons for the return clearly. Some suppliers require specific forms or documentation to process returns or exchanges. If a fabric does not meet your needs or expectations, promptly addressing the issue allows suppliers to respond effectively.

Keep all original packaging intact during the return process. Many suppliers prefer items returned in their original state. If an exchange is desired, inquire if the supplier holds similar fabrics in stock. This inquiry ensures a replacement that matches your project needs without additional delay.

Maintain an organized record of all returns and exchanges. Doing so aids future transactions and strengthens relationships with suppliers. Building rapport with suppliers often results in better service for future purchases.

Troubleshooting

Troubleshooting common issues with wholesale fabrics can enhance your purchasing experience and project outcomes. Addressing problems early ensures you maintain the quality and integrity of your fabric inventory.

Identifying Fabric Quality Issues

Identifying quality issues with fabrics requires thorough examination. Inspect samples closely before placing large orders. Look for inconsistencies in color or dye lot variations, as even slight differences can affect the final project. Check for flaws such as snags, tears, or irregularities in texture. Feel the fabric for smoothness and consider weight; heavier fabrics suit different projects than lighter ones.

Verify the fabric’s composition by consulting the label or information from the supplier. Cotton and polyester may exhibit different behaviors during cutting and sewing. Understand that natural fibers like silk can be more delicate while synthetic options often provide durability. Perform a burn test to evaluate fiber content, as this provides insight into fabric properties.

Document any defects or issues immediately. Take clear photographs and include measurements to support your case. Communicate with the supplier promptly, as many offer a return or exchange policy for defective materials. Familiarize yourself with these policies before purchasing to streamline resolution processes.

Solving Pricing Discrepancies

Solving pricing discrepancies involves careful analysis of all components involved in your wholesale purchase. Begin by comparing quotes from different suppliers. Ensure you account for shipping costs and potential discounts. Pricing may vary based on order volume, fabric type, and supplier terms.

Perform a detailed analysis of your pricing agreement. Check minimum order quantities and bulk pricing options, as larger orders often yield better rates. Approach suppliers with any pricing discrepancies by presenting clear evidence, including quotes and relevant information.

Maintain open communication with suppliers. Ask questions about their pricing structure and request clarifications regarding any unexpected costs. Inviting dialogue can often lead to solutions and unpacking the rationale behind pricing changes.

Seek loyalty programs and inquire about ongoing or seasonal promotions. Building a relationship with suppliers can provide insights into cost-saving opportunities. Stay updated on market trends, as fluctuations in fabric demand may impact pricing.

Identifying fabric quality issues and solving pricing discrepancies are key to successful wholesale fabric purchasing.

Tips for Successful Wholesale Fabric Buying

Staying Updated on Trends

Staying informed about current trends in fabric can enhance your buying strategy. Monitor industry publications and websites, as they provide insights on popular styles, patterns, and colors. Attend trade shows or textile fairs where you can see the latest fabric innovations firsthand. Engage in online forums or social media groups focused on fabric buying. Gathering feedback from fellow designers and crafters gives added perspectives on what works in the market. Observe your competitors and their product offerings to identify what attracts customers. Always seek new suppliers that can offer the latest fabrics. These strategies keep your inventory fresh and appealing, aligning with consumer desires.

Utilizing Fabric Samples

Utilizing fabric samples is a vital step in wholesale fabric buying. Request samples from suppliers before placing large orders. Assess characteristics such as texture, weight, and color. Test how the fabric performs during cutting and sewing to ensure it meets your requirements. Maintain a sample library of different materials for reference, which helps when deciding on future projects. Evaluate the consistency of the fabric across samples, checking for matching dye lots. Consider durable samples that reflect actual representations of larger orders. Gathering multiple samples gives a better understanding of the range available, enhancing overall purchasing confidence.

Conclusion

Exploring the world of wholesale fabrics opens up a realm of possibilities for your creative projects. By leveraging the benefits of bulk purchasing you can save money while gaining access to an extensive variety of materials.

With the right suppliers and a solid understanding of fabric quality you can elevate your designs and streamline your workflow. Remember to stay organized and informed about industry trends to maximize your wholesale fabric experience.

Embrace the advantages of wholesale fabrics and watch your crafting or fashion projects flourish.

Frequently Asked Questions

What are wholesale fabrics?

Wholesale fabrics are textiles sold at lower prices when purchased in large quantities. They cater to fashion designers, crafters, and businesses seeking diverse materials like cotton, polyester, silk, and linen.

Why should I buy fabrics wholesale?

Buying fabrics wholesale can save money and provide access to a wide variety of colors, patterns, and textures. It allows buyers to stock up on essential materials while benefiting from consistent quality and reliable availability.

How do I choose a reputable wholesale fabric supplier?

To choose a reputable supplier, research online platforms, attend local trade shows, and compile a list of potential vendors. Check reviews, assess their offering, and ensure they meet your project needs.

What should I consider when evaluating fabric quality?

When evaluating fabric quality, order samples to assess texture, weight, and durability. Check for certifications that indicate quality standards and consider the fabric’s origins and sustainability practices.

How can I negotiate the best price for wholesale fabrics?

Negotiate prices by researching market rates, asking for discounts, and being flexible with your order. Building relationships with suppliers can also lead to loyalty discounts for larger orders.

What is the best way to store wholesale fabrics?

Store wholesale fabrics in a cool, dry place using fabric bolts or rolls to prevent creases. Organize them by type for easy access and use clear bins for visibility while regularly checking for pests.

What tools do I need for cutting wholesale fabrics?

Essential tools for cutting wholesale fabrics include rotary cutters, high-quality fabric scissors, straight edge rulers, measuring tapes, and chalk or fabric markers to ensure precision in your projects.

How do I address issues with defective wholesale fabrics?

Inspect samples before larger orders and document any defects by taking pictures. Communicate with suppliers about issues clearly, and follow their return policies for replacements or refunds as needed.

What should I do if there are pricing discrepancies with my supplier?

To resolve pricing discrepancies, compare quotes from different suppliers, analyze your pricing agreements, and keep open communication with suppliers to clarify any misunderstandings.

How can I stay updated on wholesale fabric trends?

Stay updated by monitoring industry publications, attending trade shows, and engaging with online communities. Keeping a sample library can also help you track trends and assess fabric characteristics.