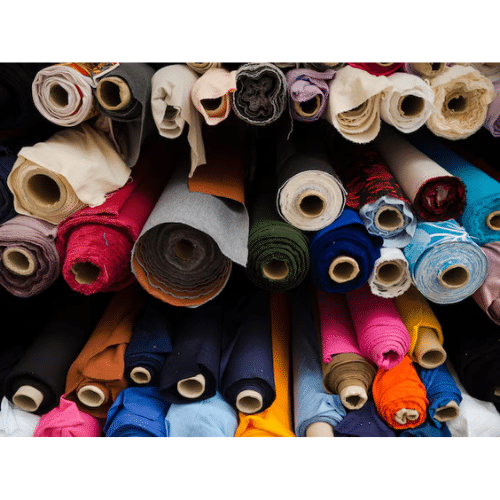

If you’re in the textile industry or a DIY enthusiast, understanding the world of fabric wholesale can open up a treasure trove of opportunities. Buying fabric in bulk not only saves you money but also gives you access to a wider variety of materials, colors, and patterns that retail stores often don’t carry. Whether you’re creating custom clothing, home decor, or crafting unique projects, sourcing your fabrics wholesale can significantly enhance your creativity and profitability.

In today’s competitive market, knowing where to find reliable suppliers and how to navigate pricing can make all the difference. You’ll discover tips on selecting the right fabrics for your needs, building lasting relationships with wholesalers, and maximizing your savings. Embrace the potential of fabric wholesale and elevate your projects to new heights while keeping your budget in check. Let’s dive into the essentials that will help you make informed decisions in this vibrant industry.

Understanding Fabric Wholesale

Understanding fabric wholesale involves recognizing the benefits and processes associated with purchasing fabric in bulk. Buyers gain significant advantages in cost, variety, and accessibility when they choose wholesale options.

Benefits of Fabric Wholesale

- Cost Savings: Buying fabric in larger quantities typically results in lower prices per yard. Expect discounts that can range from 10% to 50% compared to retail prices.

- Variety of Fabrics: Suppliers often carry a broader selection of materials, colors, and patterns. This variety allows access to unique fabrics not found in local stores.

- Consistent Supply: Wholesalers can offer the same fabric in bulk, ensuring consistent quality and color for larger projects. This is particularly important for fashion designers and businesses.

- Customization Opportunities: Many wholesale suppliers provide options for custom fabrics. You can request specific patterns or even personal designs, expanding your creative possibilities.

Steps to Buy Fabric Wholesale

- Research Suppliers: Start by researching reputable fabric wholesalers. Look for reviews and ratings from other customers to gauge reliability and quality.

- Request Samples: Many wholesalers offer fabric samples. Order samples to evaluate quality, texture, and color before making larger purchases.

- Understand Pricing: Familiarize yourself with pricing structures. Wholesalers often have tiered pricing based on quantity ordered, so know how much you plan to buy.

- Build Relationships: Develop relationships with your suppliers. Frequent communication may lead to better deals or exclusive offers.

- Place Orders: When ready, place orders. Ensure you provide accurate measurements and specifications to avoid errors.

Important Considerations

- Minimum Order Quantities: Most wholesalers set minimum quantity requirements. Clarify these before ordering to avoid unnecessary expenses.

- Shipping Costs: Review shipping options and costs associated with wholesale orders. These can affect total savings, especially for large purchases.

- Return Policies: Understand the return policies of your chosen wholesalers. This ensures options in case of defects or wrong orders.

- Trends and Demand: Stay informed about current fabric trends. Knowing what is in demand can help select fabrics that may sell well if you plan to resell.

- Price Comparison: Regularly compare wholesale prices with retail offerings to assess fairness and competitiveness.

By comprehensively understanding fabric wholesale, you can maximize your savings, access unique materials, and enhance your projects.

Benefits Of Buying Fabric Wholesale

Buying fabric wholesale delivers several advantages for businesses and individuals involved in textiles and DIY projects. You gain access to cost savings, diverse options, and various business opportunities by choosing wholesale.

Cost Savings

Significant savings occur when purchasing fabric in bulk. Wholesale prices are lower than retail prices because suppliers sell larger quantities. For example, cutting costs by 30% or more is common when buying fabric wholesale. This reduction applies to various fabrics, such as cotton, polyester, or specialty materials like silk.

Reduced shipping costs enhance savings further. Suppliers often offer better shipping rates for larger orders, which decreases the per-yard cost of delivery. For instance, ordering 100 yards may incur a smaller shipping fee per yard than ordering 10 yards.

Avoiding small-order fees also aids in saving money. Retailers frequently charge fees for small quantities, while wholesalers do not impose such charges. Financial efficiency occurs when you choose wholesale for your fabric needs, positively affecting your overall budget.

Variety Of Choices

A broader selection exists when buying fabric wholesale. You access numerous colors, patterns, and materials unavailable in local stores. Wholesalers typically stock large inventories from various manufacturers. For instance, you might find exclusive prints or specialty fabrics that enhance your projects’ uniqueness.

Substantial options for customization enable you to find fabrics that match specific design themes or project requirements. Whether looking for specific textures for home decor or unique colors for fashion projects, wholesalers provide diverse choices.

Thicker varieties and distinct patterns often appear with wholesale fabrics. You may notice unique styles and patterns appealing to niche markets or specialized projects, which enhances creativity.

Business Opportunities

Abundant business prospects arise from buying fabric wholesale. For small businesses, bulk purchasing leads to increased inventory, allowing you to serve more customers effectively. You can offer a wider range of products, from home goods to clothing, meeting various market needs.

Establishing supplier relationships can lead to benefits like exclusive deals and early access to new fabrics. Building a reliable supplier network fosters collaboration and insight into upcoming fabric trends, providing a competitive edge.

Innovative product lines can emerge from access to unique fabrics. By experimenting with new materials and patterns, you create distinctive offerings that appeal to customers and differentiate your brand in the market. Consistent access to wholesale fabric sets the stage for growth and success in your business endeavors.

How To Start Buying Fabric Wholesale

Starting with wholesale fabric purchases offers various benefits. This guide provides straightforward steps to help you make informed decisions.

Research And Identify Suppliers

Research begins by searching online for fabric wholesalers. Utilize keywords like “fabric wholesalers near me” or “bulk fabric suppliers.” Look for suppliers specializing in various materials such as cotton, linen, and polyester. Visit their websites to check fabric types, product ranges, and pricing details.

Identify multiple suppliers to compare options. Read customer reviews and testimonials to assess reliability. Join online forums or social media groups focused on fabric buying to gather recommendations from other buyers. Attend trade shows or fabric expos to meet suppliers in person.

Compile a list of potential suppliers with contact details. A list helps streamline communication when requesting price quotes or more information.

Evaluate Supplier Credentials

Evaluating supplier credentials is essential for ensuring quality and reliability. Review supplier experience in the industry. More established suppliers often have a proven track record, providing peace of mind.

Check for certifications that verify quality standards. Some common certifications include ISO or Oeko-Tex, which indicates compliance with safety and environmental standards. Confirm if the supplier has any complaints or legal issues registered against them.

Request references from previous customers to gain insights into their experiences. Contact these references directly; ask about product quality, delivery time, and customer service.

Review the supplier’s website for any additional information about their policies, such as minimum order quantities and return options. Look for transparency in pricing and communication. Trustworthy suppliers will answer your questions promptly and provide clear information.

Request Samples

Requesting fabric samples from suppliers is necessary before making larger purchases. Samples help assess quality, texture, and color, ensuring they meet your project needs.

Reach out to your shortlisted suppliers and request samples of specific fabrics. Some suppliers might offer free samples, while others may charge a small fee. Specify fabric types and quantities when making your request.

After receiving the samples, evaluate them by checking texture, weight, and print clarity. Conduct any tests necessary to determine durability and colorfastness depending on your intended use.

Once satisfied with the samples, you can proceed with placing a wholesale order. Having physical samples enables informed decisions, minimizing risks associated with fabrics that do not meet expectations.

Materials Needed

For successful fabric wholesale purchases, gather essential materials that help in decision-making and ensure quality.

Fabric Swatches

Fabric swatches provide a tactile way to evaluate textures, patterns, and colors. Obtain various swatches from suppliers to compare choices before committing to larger orders. Look for swatches that represent different types of fabrics you plan to purchase, such as cotton, polyester, and linen. Assess the weight, weave, and drape of each fabric swatch. This evaluation helps determine which materials suit your project requirements best.

When requesting swatches, specify fabric types and colors relevant to your needs. Suppliers often provide samples for free or at a nominal cost. Store the received swatches organized to make comparison easy when finalizing fabric selections. Use fabric swatches to visualize how they fit within your overall project theme. This process creates a clearer picture of the final outcome and helps prevent costly errors.

Measuring Tools

Measuring tools are crucial for bulk fabric purchases. Accurately assess how much fabric you require for your projects using measuring tools like tape measures and rulers. A flexible tape measure ensures precise measurements around curves and corners while a ruler offers straight-line guidance.

Determine the dimensions of your project by measuring existing items or sketching out plans. Calculate the total fabric needed by factoring in seam allowances and design features like hems or pleats. Ensure to measure multiple times for accuracy.

Use a fabric calculator online to assist in determining how much material to order based on your measurements. These tools simplify calculations and adjust for different fabric widths. Keep measuring tools handy when planning to visit wholesalers in person, allowing quick assessments of potential purchases. Accurate measurements lead to effective bulk buying, reducing waste and ensuring you receive the correct amount of fabric for your projects.

How To Place A Wholesale Order

Placing a wholesale order involves several clear steps that guarantee a smooth transaction. Following these steps ensures you obtain the right fabric for your needs.

Creating An Account With Suppliers

Creating an account with suppliers starts with selecting reliable ones. Use online directories or trade shows to find potential fabric wholesalers. After identifying a supplier, visit their website to fill out an application form. The application usually requires basic information like your business name, address, and tax ID number.

Once your application is submitted, expect to receive a confirmation email. Confirm your email address to activate your account. Many suppliers also offer an account management dashboard allowing you to track orders, view previous purchases, and manage payment information efficiently. Having a registered account with suppliers streamlines the ordering process, making future orders quick and easy.

Choosing The Right Fabrics

Choosing the right fabrics involves understanding your project requirements. Begin by defining the purpose of the fabric. Determine whether it will be used for clothing, upholstery, or crafts. Each type of project has specific fabric needs. For instance, cotton is suitable for clothing, while polyester works well for upholstery.

Next, review fabric samples available from suppliers. Examining samples provides insights into texture, weight, and color. Use swatches to compare different materials. Check their durability, ease of care, and colorfastness. Prioritize fabrics that align with your project’s aesthetic and functional aspects.

Moreover, inquire about the availability of specific colors and patterns in bulk. When selecting fabrics, consider the trend of the season and customer preferences. Selecting the right fabric enhances product quality and consumer satisfaction.

Understanding Minimum Order Quantities

Understanding minimum order quantities (MOQs) is crucial for budget planning. MOQs define the smallest amount of fabric you can purchase from a supplier. Suppliers set MOQs to ensure profitability in bulk sales. For example, some suppliers may have MOQs of 10 yards, while others may require 50 yards or more.

Before placing an order, verify the supplier’s MOQ policy. Assess whether the MOQ aligns with your needs and budget. If the MOQ is high, consider discussing alternatives with the supplier, such as ordering different fabric types to meet the required quantity.

In some cases, suppliers may allow you to mix fabrics to meet MOQs. Always confirm this option before finalizing your order, as it can help reduce excess fabric expenses. Understanding and negotiating MOQs ensures that you maintain control over your spending while securing needed materials.

Tips For Successful Wholesale Fabric Purchasing

Negotiating Prices

Negotiating prices proves essential when purchasing fabric wholesale. Focus on understanding the market rate for various fabrics. Research what other buyers pay for similar materials. Consider factors such as fabric type, quality, and the supplier’s reputation. Initiate discussions with suppliers regarding pricing structures. Express interest in bulk purchases, as larger quantities can lead to discounts. Provide a clear request for pricing terms and potential concessions. Demonstrate loyalty toward suppliers. Suppliers often appreciate long-term relationships and may offer better terms to established customers. Be clear about your budget and assertive in negotiations. Don’t hesitate to ask for lower prices or additional perks such as free shipping. Explore different suppliers to compare offers, as this creates leverage in negotiations and helps secure the best deal.

Building Relationships With Suppliers

Building strong relationships with suppliers greatly enhances your wholesale fabric purchasing experience. Establish open and honest communication with suppliers. Share your business goals and fabric needs, making it easier for them to understand how they can assist you. Frequent communication keeps channels open and allows for better service. Regular check-ins with your suppliers also help maintain the relationship. Show appreciation for their efforts. A simple thank-you can go a long way. Attend trade shows and industry events to deepen connections. Meeting suppliers in person allows for discussions beyond just transactions, fostering mutual understanding. Be consistent in your purchasing habits. Frequent orders demonstrate reliability, which may lead to better prices over time. Suppliers value their committed customers, resulting in improved terms and personalized service.

Staying Updated On Market Trends

Staying updated on market trends is crucial for successful wholesale fabric purchasing. Follow industry publications and websites for the latest insights. These resources often provide information about emerging trends in fabrics, colors, and patterns. Utilize social media platforms to engage with creative communities. Interactions with designers and other fabric buyers can provide valuable insights and help identify popular materials. Attend trade shows and fabric fairs to observe recent innovations firsthand. Networking at these events enables you to gather information and see new products in action. Monitor competitors and peer businesses to gauge popular fabric choices. Understanding what others are buying guides your own purchasing decisions. Consider subscribing to newsletters from major wholesalers and fabric retailers. These updates keep you informed about new arrivals, sales, and exclusive offers, ensuring you stay on top of market trends.

Common Issues In Fabric Wholesale

Delays In Shipping

Shipping delays frequently occur in fabric wholesale. Shipping delays impact project timelines. Factors contributing to these delays include weather conditions, logistical challenges, and customs clearance procedures. When placing an order, confirm the expected shipping dates with suppliers to anticipate any potential issues. Explore multiple shipping options, including air and ground transport, to find the fastest solution. Utilizing reliable couriers can minimize delays. Maintain open communication with your supplier, ensuring they provide updates on shipping status. Establish realistic timelines for project scheduling by factoring in possible delays, allocating extra time for unforeseen circumstances. Tracking your shipments allows you to monitor progress and intervene if necessary.

Quality Control Problems

Quality control issues can significantly affect your wholesale fabric purchases. Subpar fabric quality results in project setbacks and financial loss. To mitigate this, request samples before finalizing larger orders, which allows you to evaluate the fabric’s weight, texture, and color. Develop a list of specific quality standards. Communicate these standards clearly with your suppliers to ensure they understand your expectations. Regularly inspect incoming shipments to check for defects or discrepancies. Document any quality issues thoroughly; this helps in addressing problems with suppliers promptly. Establish a quality assurance process by collaborating with suppliers for better consistency. Maintaining a strong business relationship encourages suppliers to prioritize higher quality.

Incorrect Orders

Incorrect orders add complications to your wholesale fabric purchasing process. Miscalculating the quantity or fabric type leads to wasted time and money. To avoid this, verify all details before placing orders. Double-check the SKU numbers, fabric types, colors, and quantities. Communicate your order details clearly and consider following up with suppliers to confirm accuracy. Maintain a detailed order history to reference in case of discrepancies. If errors occur, handle them promptly by notifying suppliers immediately. Secure a return or exchange policy before making purchases, ensuring you can address incorrect orders efficiently. Keeping accurate records helps streamline dispute resolutions and ensures better future transactions.

Troubleshooting Wholesale Fabric Problems

Navigating challenges in wholesale fabric procurement requires a clear strategy. Below are solutions to common problems encountered in this process.

Solutions For Shipping Delays

Shipping delays can disrupt project timelines and increase costs. Confirm shipping dates directly with your supplier before placing orders. Ensure clear communication about expected delivery times. Explore multiple shipping options such as express services or consolidated shipments, which may reduce delays. Monitor shipments through tracking numbers for real-time updates. Should issues arise, maintain consistent contact with the carrier to address any complications. Consider adjusting your schedule to accommodate potential delays, allowing buffer time for late arrivals.

Table of common shipping strategies:

| Strategy | Description |

|---|---|

| Confirm Shipping Dates | Verify delivery timelines directly with suppliers. |

| Explore Shipping Options | Consider express or consolidated shipping services. |

| Monitor Shipments | Use tracking numbers for updates on deliveries. |

| Maintain Contact | Keep open lines of communication with carriers. |

| Adjust Schedules | Allow extra time for receiving fabric. |

Handling Quality Discrepancies

Quality discrepancies can impact your projects significantly. Request samples before committing to large orders. This step allows evaluation of fabric quality, texture, and color accuracy. Establish clear quality standards with your supplier to avoid misunderstandings. Inspect incoming shipments immediately upon arrival. If discrepancies occur, document issues with photos and details for clarity. Engage in open dialogue with suppliers to discuss problems and solutions. Maintain records of quality expectations to streamline future orders.

Table of quality management steps:

| Step | Description |

|---|---|

| Request Samples | Order samples to evaluate fabric characteristics. |

| Establish Quality Standards | Define expectations clearly with suppliers. |

| Inspect Shipments | Check fabrics upon arrival for quality assurance. |

| Document Issues | Keep records of any quality discrepancies with evidence. |

| Engage with Suppliers | Communicate openly to resolve quality concerns. |

Resolving Order Errors

Order errors can lead to wasted time and resources. Verify order details before submission, checking quantities and fabric specifications. Maintain accurate records of all orders to facilitate dispute resolution. In case of errors, contact your supplier immediately with details of the incorrect order. Be prepared to provide supporting documentation such as invoices or correspondence. Negotiate solutions amicably, seeking either a replacement or a refund depending on the situation. Focus on building good relationships with your suppliers, which can help prevent issues in the future.

| Step | Description |

|---|---|

| Verify Order Details | Double-check quantities and specifications before placing orders. |

| Maintain Accurate Records | Keep detailed records of all orders and correspondence. |

| Contact Suppliers | Reach out promptly in case of order discrepancies. |

| Provide Documentation | Supply evidence like invoices to support your claims. |

| Negotiate Solutions | Seek resolution through open discussions for replacements or refunds. |

Conclusion

Embracing fabric wholesale can be a game changer for your projects. By purchasing in bulk, you not only save money but also gain access to a wider variety of materials that spark your creativity. Building strong relationships with suppliers can lead to exclusive deals and consistent quality for your needs.

Navigating the wholesale landscape might come with challenges, but with the right strategies in place, you can overcome them effectively. Whether you’re a DIY enthusiast or running a small business, fabric wholesale offers opportunities that can elevate your work and profitability. So take the leap and explore the vast world of fabric wholesale to unlock your creative potential.

Frequently Asked Questions

What are the benefits of buying fabric wholesale?

Buying fabric wholesale offers significant cost savings and a much broader selection of unique materials, colors, and patterns compared to retail stores. This approach allows for consistent supply for larger projects and customization opportunities, enhancing creativity and fulfilling specific project needs.

How do I find reliable fabric wholesalers?

To find reliable fabric wholesalers, research online, attend trade shows, and read reviews. Evaluate suppliers based on their credentials, check for customer references, and ensure they have the necessary certifications to guarantee quality and reliability.

What should I consider when purchasing fabric wholesale?

Consider factors like minimum order quantities, shipping costs, return policies, and payment terms. Additionally, always request fabric samples to assess quality and texture before placing large orders, and stay informed about fabric trends to make better purchasing decisions.

How can I maximize savings when buying fabric wholesale?

To maximize savings, build relationships with suppliers who offer exclusive deals, negotiate pricing, and order in bulk to reduce shipping costs. Assess your needs before ordering and track pricing trends to ensure you’re making the most economical choices.

What common issues should I be aware of in fabric wholesale?

Common issues include shipping delays, quality discrepancies, and incorrect orders. To address these, confirm shipping dates with suppliers, review quality standards, and double-check order details before finalizing purchases to avoid potential problems.

How can I troubleshoot shipping delays in fabric wholesale?

To troubleshoot shipping delays, confirm the shipping date with your supplier, explore multiple shipping options, and maintain open communication with carriers. Being proactive can help mitigate the impact of delays on your projects.

What steps should I follow to start buying fabric wholesale?

Start by researching and identifying suppliers, then evaluate their credentials and request fabric samples. Understand pricing structures and minimum order quantities to make informed decisions, and build strong relationships with suppliers to facilitate future purchases.